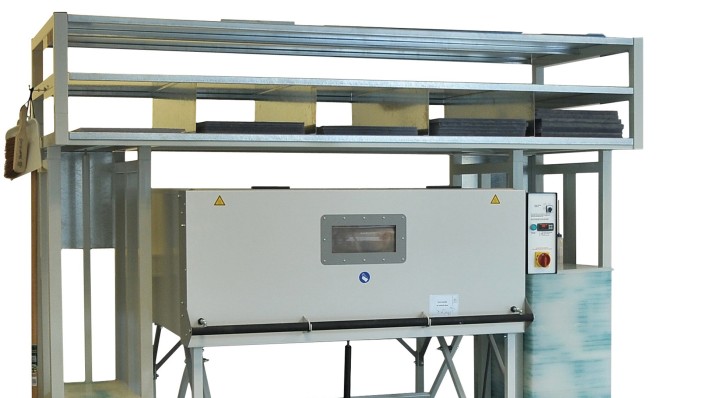

Infrared heating cabinet for sheet materials, with rotatable material cart

All benefits at a glance

All benefits at a glance

- Sensor for exact measurement of the material sag depth with acoustic and optical signal (only for models 701E40=S)

- Mobile material cart with rotation function facilitates switching between Teflon-covered work surface and vacuum forming frame quickly and saves space

- State-of-the-art infrared quartz tubes with single reflectors ensure an even heating

- Optical temperature sensor permits continuous monitoring of the material surface temperature

- Simple operation via a central element with temperature setpoint entry and timer function

- Storage function for user-defined heating processes

- Graphical progress indicator for monitoring

- Heat insulated housing (except for infrared oven 701E43), enclosed on all sides

- Space-saving sliding door

- Stainless steel front panel with 3 viewing windows

Infrared heating

Higher productivity with infrared ovens

Infrared ovens are the first choice when plastics need to be heated in the orthopaedic workshop.

The way they work makes the difference: In conventional convection ovens an object is heated by absorbing ambient heat in a closed compartment. In contrast, the heat in an infrared oven is generated in the form of electromagnetic waves absorbed by the material directly. This has many advantages: Higher speed, greater productivity and a significantly greater energy efficiency are the result.

Heat more quickly – consume less energy

An Ottobock infrared oven heats plastics in a very short time. A 4 mm thick polypropylene sheet can be heated in just 4 to 6 minutes. Infrared ovens do not need to be pre-heated – the radiant heat is fully available in an instant. This significantly reduces energy consumption in the orthopaedic workshop.

Technical data

Technical data

| Article number | 701E40=S |

|---|---|

| Version | with Sensor for programmable measurement of the blister depth for vacuum formed sockets, tower light for visualising the operating status, incl. 2-stage alarm function |

| Equipment |

|

| Material cart |

|

| Electrical connection in V/Hz/kW | 3x 400 N/PE / 50-60/ 8,5 |

| Infrared radiator | Panel heating with 18 infrared quartz tubes, with individual reflectors |

| Material | Steel, stainless steel |

| Outer dimensions WxDxH | 1.600 x 1.270 x 1.430 mm |

| Interior dimensions WxDxH | 1.300 x 1.090 x 500 mm |

| Interior volume | 709l |

| Weight | 347 kg |

Downloads

- Brochure Infrared ovens for the orthopaedic workshop 1.45 MB | PDF

Infrared ovens for the orthopaedic workshop

- 701E40=S Infrared oven with rotatable material cart

- 701E41=WS Infrared oven with removable support plate

- 701E43 Infrared oven with height-adjustable material cart

- 701E44=S Infrared oven for small plastic sizes

- Vacuum forming accessories

- 755T6=1 und 755T6=2 vacuum forming workstation with integrated vacuum pump

- 755T1=2, 755T1=3, 755T1=4 vacuum forming workstation with integrated tank

- Accessories for vacuum forming workstations

- Vacuum forming materials

Accessories

758R16=1700 Rack for infrared oven

For space-saving storage of sheet materials and vacuum forming accessories in the open space above the infrared oven.

758R17=2600 Rack for infrared oven

Offers storage shelves to the side and above the infrared oven for space-saving storage of sheet materials and accessories for vacuum forming work.