Frame and container preforms made of carbon

All benefits at a glance

All benefits at a glance

- Clean and easy processing

- Pre-determined layer structure

- Simplified fabrication and less time to fabricate a socket

- Waste of expensive reinforcement materials is minimised

- Simplified quantity control in comparison to rolled and sheet goods

Specifications

Specifications

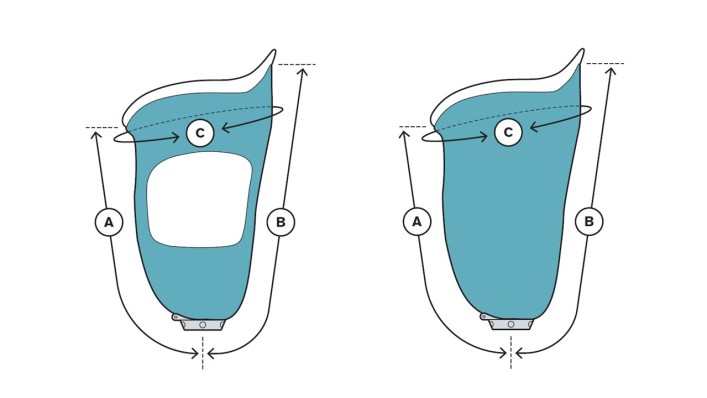

| Reference number | Description | Measurements (mm) | ||

|---|---|---|---|---|

| A | B | C | ||

| 5Z16=280X700X150 | Frame preform | 280 | 370 | 700 |

| 5Z16=350X700X150 | 350 | 500 | 700 | |

| 5Z17=280X700X150 | Container preform | 280 | 370 | 700 |

| 5Z17=350X700X150 | 350 | 500 | 700 | |

| Reference number | 5Z16 Frame preform 5Z17 Container Preform | |

|---|---|---|

| Package contents | Three preforms for fabricating a prosthetic socket | |

| Order by | 1 pc. | |

| Recommended components | 4R41, 4R42, 4R42=1, 4R43, 4R89, 4R114, 4R111=T, 4R111=N, 4R116, 4R116=T, 4R117, 4R117=T, 4R119=NT, 4R119=T, 4R119, 4R119=N, 4WR95=1, 4WR95=2 | |

Processing instructions

Processing instructions

- Apply the M/L section with the short side oriented medially. Round the edges when shortening to the correct length.

- Wrap around the radial section: position the reinforcement triangle medially in the perineum with the point towards the end of the residual limb. The radial section can be used for left-hand (carbon on the outside) and right-hand (carbon on the inside) sockets. Perform the first casting with the M/L section and the radial section.

- Attach the anchor and position the faces of the star so they are centred over the anchor arms. Perform the second casting with the anchor and star.

The carbon preforms can be processed with all Ottobock resins.

Downloads

Please download file:

- Frame and container preforms made of carbon 176.41 kB | PDF

Frame and container preforms made of carbon

Efficient reinforcement for prosthetic sockets

- Frame preform 5Z16

- Container preform 5Z17